Introducing aerospace bracket of the future!

3DFiT made composite bracket possible

CarbonForm 3DFiT unlocks a new era of aerospace composite brackets: lighter, stronger, and mold free.

3D Fiber Tethering (3DFiT) enables the direct placement of continuous carbon fibers along load paths, producing monolithic brackets without joints, molds, or machining faster, cleaner, and built for flight.

Traditional aerospace engine brackets are typically machined from solid metal blocks

Excess weight that reduces fuel efficiency and increases emissions

Complex multi-part assemblies that require fasteners or bonding

High material waste (up to 90% in subtractive machining)

Long lead times for tooling, fabrication, and post-processing

Our 3D Fiber Tethering (3DFiT) offers

Printing monolithic composite brackets with no joints or fasteners

Steering continuous carbon fibers along optimized load paths in 3D space

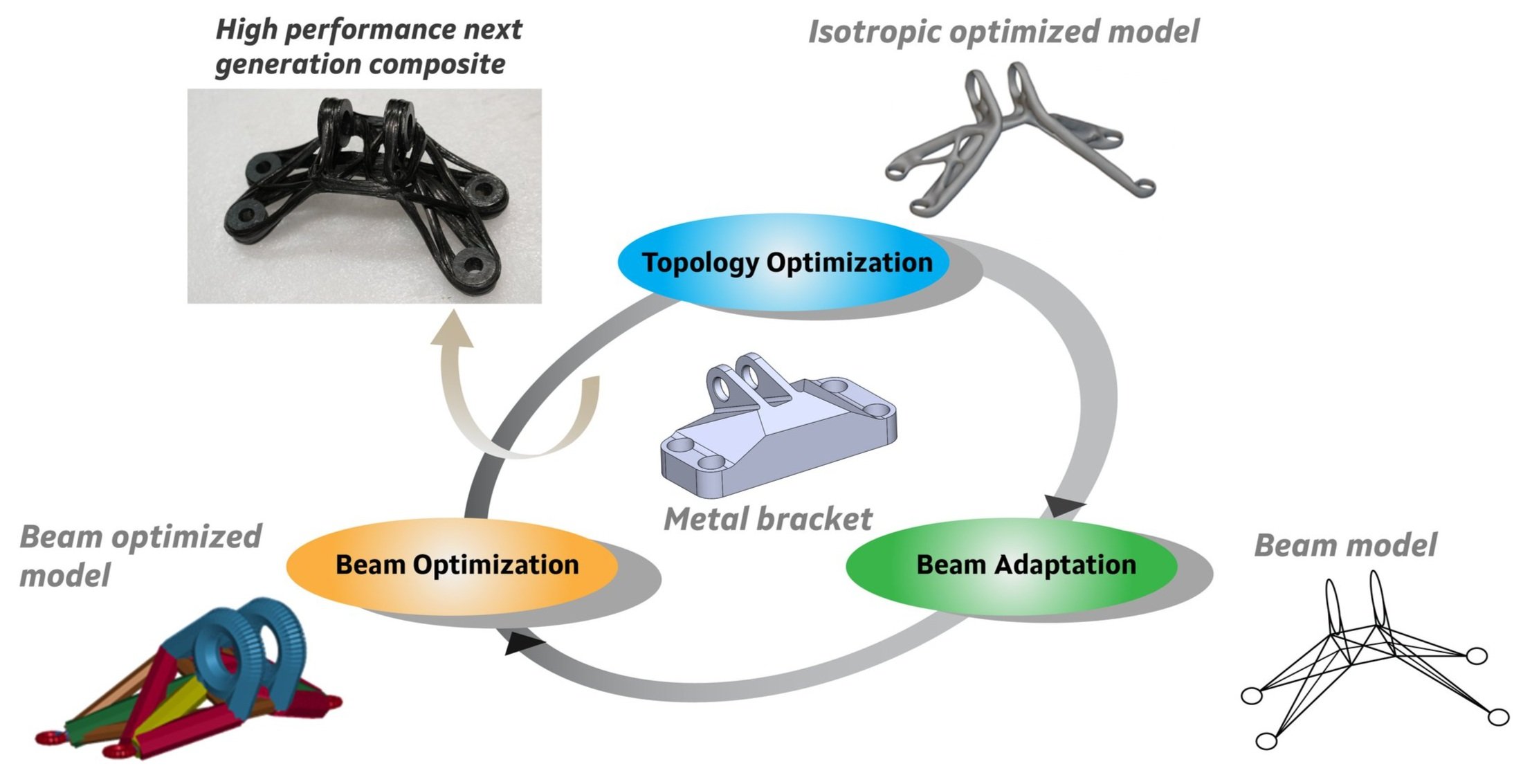

Enabling topology-optimized designs for anisotropic fiber 3D architectures

Eliminating molds or machining for faster product design and production

A remarkable 93.5% weight reduction was achieved !