3DFiT: 3D Fiber Tethering

High-Performance Continuous Carbon Fiber Thermoset Composites Additive Manufacturing:

10X stronger than metals

80% lighter than metals

First-ever true 3D composite

Excellent performance

Continuous Fiber: dry tow/tape

Wide selection of true thermoset resins

In-printer resin impregnation

High fiber volume fraction (>60%)

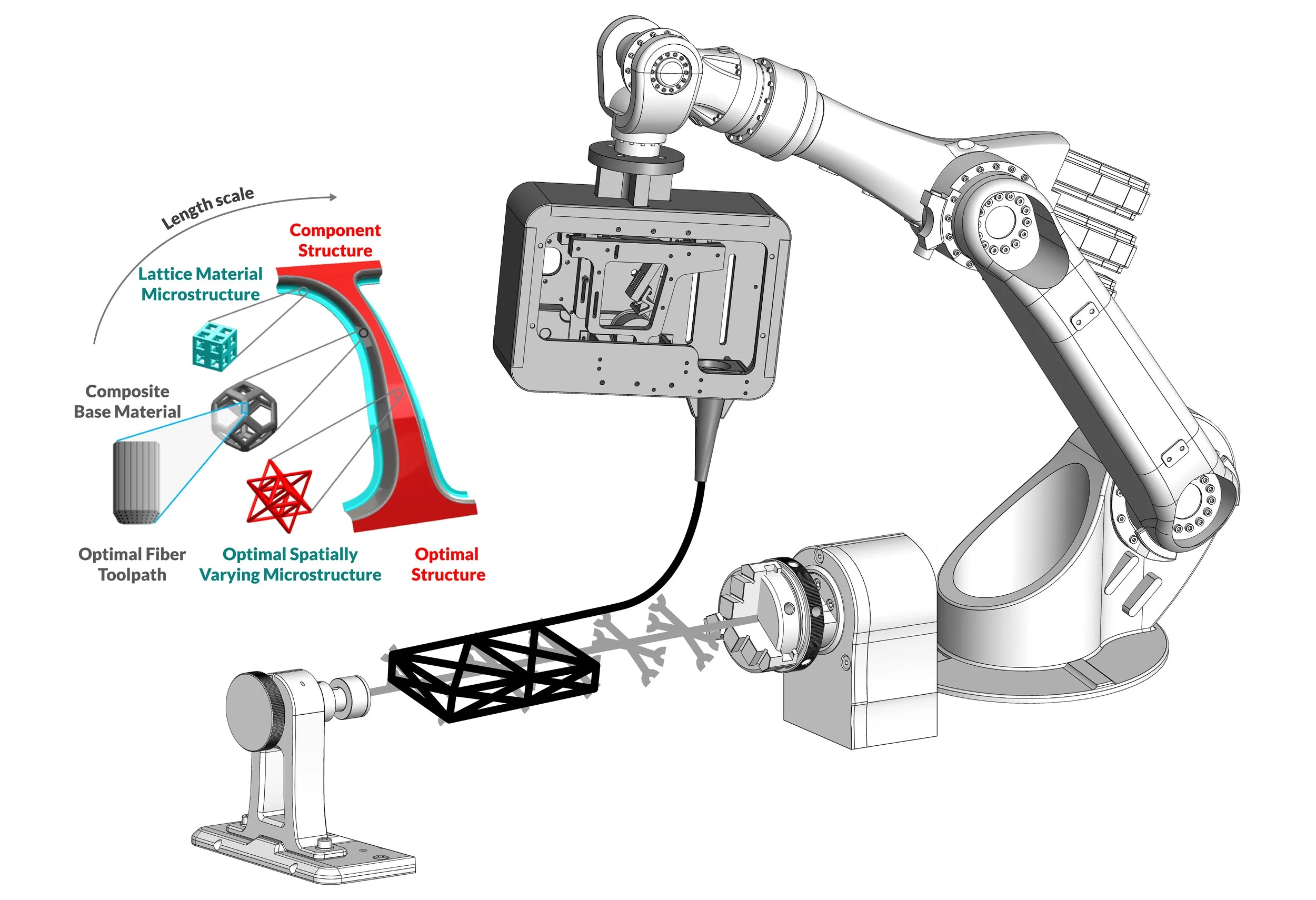

True 3D spatial fiber placement

3D Fiber Tethering (3DFiT) is a cutting-edge additive manufacturing technology developed at the University of Delaware’s Center for Composite Materials (UD-CCM)—a globally recognized leader in composite innovation, and supported by the U.S. Department of Energy’s ARPA-E program. 3DFiT enables the creation of continuous fiber-reinforced thermoset composite structures with fully 3D, joint-free geometries, eliminating the need for molds or fasteners.

Unlike other 3D printing processes that rely on UV-cured resin or thermoplastics, 3DFiT uses true thermoset resins (e.g., epoxy), ensuring high service temperature, outstanding mechanical strength, and exceptional chemical resistance. The technology is powered by a deep tech team of composite manufacturing experts, resin chemists, structural mechanics researchers, computational modelers, and automation engineers—bringing together domain expertise across materials, design, and robotics. With 3DFiT, we deliver next-generation solutions for aerospace, automotive, defense, and energy systems where structural performance and reliability are non-negotiable.